Machine detection replaces manual detection,It can scientifically extend the service life of wire rope and reduce the cost of wire rope

|

|

|

|

Winner of 2018 OTC Innovation Award on New Technology

TCK.W TCK.W Automatic Real-time Online Wire Rope Inspection System will revolutionize periodic human visual inspection and bring in-process safety monitoring to its highest state through continuous inspection during operation.

Won the highest prize of the 2022 National Subversive Technology Innovation Competition..

Disruptive technology is an innovative technology that can change the rules of the game. It will surpass the original technology and produce substitution, with a transformative effect that changes the trajectory of technological evolution and upends the status quo.

TCK.W has 35 core patents for the internationally leading "magnetic memory-based weak magnetic nondestructive testing technology", 3 invention patents in the United States, the European Union, and Japan, and 25 software copyrights,The series of products have passed the US FCC certification, the EU CE certification, the Canadian IC certification, and the German TUV certification,ISO9001 Quality Management System Certification and ISO14001 Environmental Management System Certification……more

Machine detection replaces manual detection,It can scientifically extend the service life of wire rope and reduce the cost of wire rope

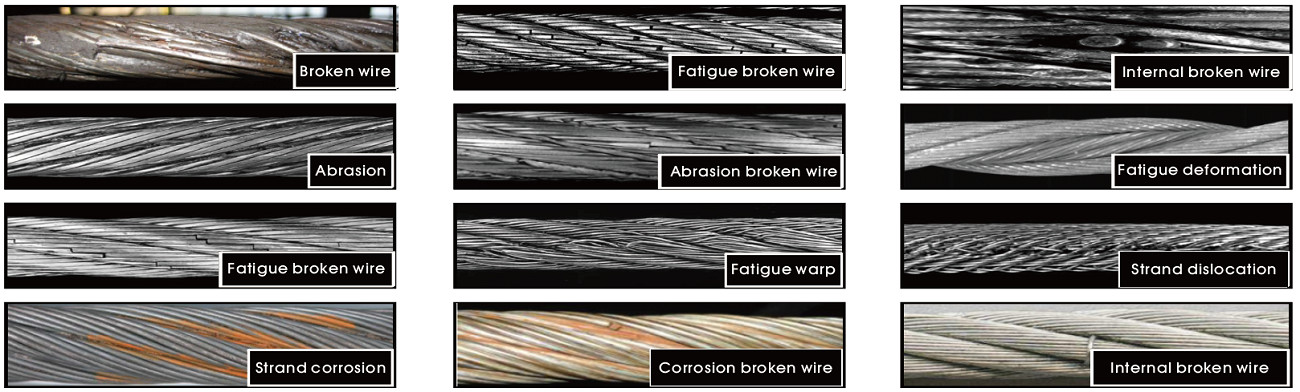

t can inspect all kinds of wire rope flaws such as internal, external broken wire, abrasion, corrosion, deformation, fatigue etc.

The elevator wire rope inspection technology invented by TCK.W and successfully solve the technical problem of wire rope detection.

After TCK. W system is installed in the main belt of a mine,not only ensures the operation safety of the conveyor belt, but also creates huge economic benefits.

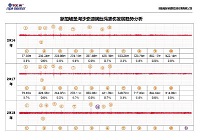

Inspection rate

Safety lifting of steel wire rope to a higher level

Serious flaw: LMA reaches 80%-100% of discard upper limit, real-time detectability 100%

Severe flaw: LMA reaches 60%-80% of discard upper limit, real-time detectability 100%

Medium flaw: LMA reaches 40%-60% of discard upper limit, real-time detectability 100%

Minor flaw: LMA reaches 20%-40% of discard upper limit, real-time detectability >95%

Slight flaw: LMA reaches 20% of discard upper limit, real-time detectability >85%

Inspection repeatability

Accurate measurement of wire rope diameter reduction

Serious flaw: 100%

Severe flaw: 100%

Medium flaw: 100%

Minor flaw: 99%

Slight flaw: 95%

Inspection Accuracy

Accurate identification of steel wire rope damage states such as deformation, corrosion, and wear.

LMA inspection uncertainty: <±1%;

Broken wires q ● uantitative error in one lay length: <1 wire*

Wire rope dia. measure error: ±1%*

Measuring error of wire rope length:<0.2%

Flaw positioning accuracy:≥99%;

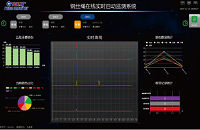

TCK.W-Wire rope online automatic monitoring system

Machine intelligence detection replaces manual detection, and safety monitoring is implemented during production, elevating the safety of steel wire rope to a higher level.

Real-time perception, monitoring, evaluation and early warning of steel wire rope to complete the transformation from post-emergency response to pre-emergency prevention

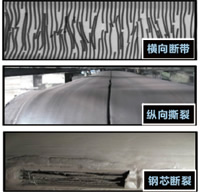

TCK.W-Steel cord conveyor belt online automatic monitoring system

No X-ray radiation, harmless to human body, energy-saving and environmental protection, transverse breaking, longitudinal tearing, online real-time safety monitoring

Real-time monitoring of major hidden dangers such as horizontal belt breakage and longitudinal tear of conveyor belt

Wire rope online automatic monitoring system

Real-time online monitoring and evaluation of steel wire rope, including detection of broken wires, wear, corrosion, fatigue, cage assembly, deformation, and other damages.

The results of repeated testing on the same steel wire rope are basically the same, realizing the transformation of steel wire rope from traditional testing to intelligent monitoring, from post-emergency to pre-emergency prevention;

The damage values of the same steel wire rope detected repeatedly are basically the same;

The sensor is 30mm away from the surface of the steel wire rope, with strong passing ability, and the high-speed passing of the steel wire rope is not affected. Online detection can be achieved.

Steel cord conveyor belt online automatic monitoring system

It can detect various damages such as lateral belt breakage, longitudinal tear, bare steel core, edge wear, etc.

Safety monitoring and production operation are synchronized, and real-time alarms are triggered for potential hazards such as belt breakage and longitudinal tearing. Advanced technological means provide maintenance basis, ensuring safety, cost reduction, and efficiency improvement.

On-line monitoring of lateral belt breakage, steel core movement, broken strands and broken cores, and real-time alarms for major potential hazards. Reducing manual inspection time and increasing conveyor belt operation time.

Real-time monitoring and alarm for longitudinal tear, edge wear, rubber cracking, and bare steel core. Reducing power consumption dedicated to conveyor belt inspection and achieving significant energy-saving effects.

Customer Stories

A delegation of 9 people from a Russian mining company visited TCK.W to discuss cooperation

TCK.W

2023-10-20

Recently, TCK.W welcomed a group of guests from a ……

headline news

Accident Cases

Corporate News