who I

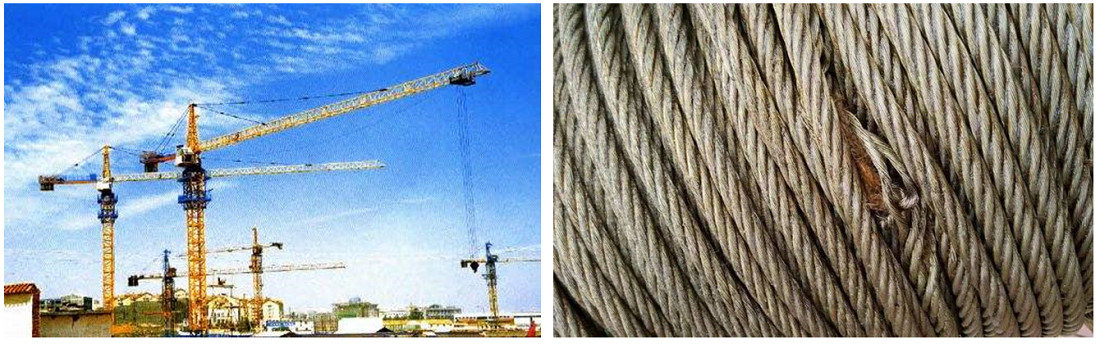

am——Wire Rope Online Inspection System For tower crane

The steel wire rope is the lifeline of the tower crane, and the accident of

steel wire rope breaking is one of the most catastrophic accidents on the tower

crane operation site.

High-risk and vulnerable, with huge consumption; 2. Frequent rope-breaking

accidents, resulting in significant casualties and property losses; 3. Lack of

technical means for safety supervision, posing a major long-term hazard.

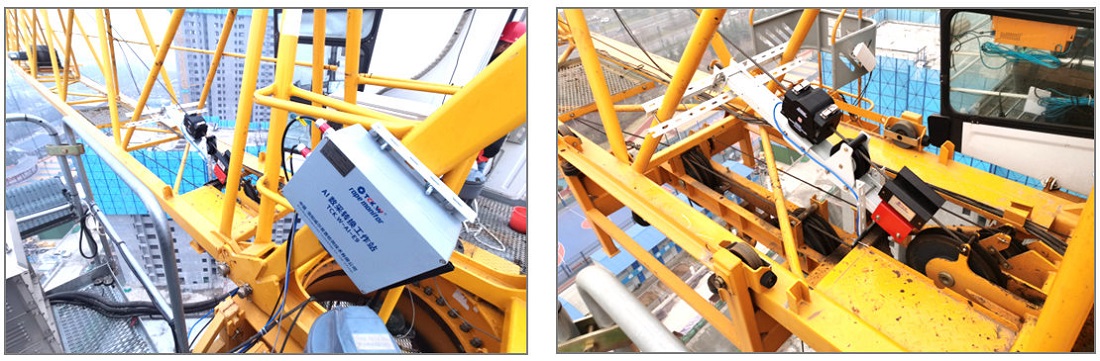

Due to high-altitude operations, the safety inspection of tower crane wire

ropes is almost absent due to factors such as working environment and harsh

conditions.

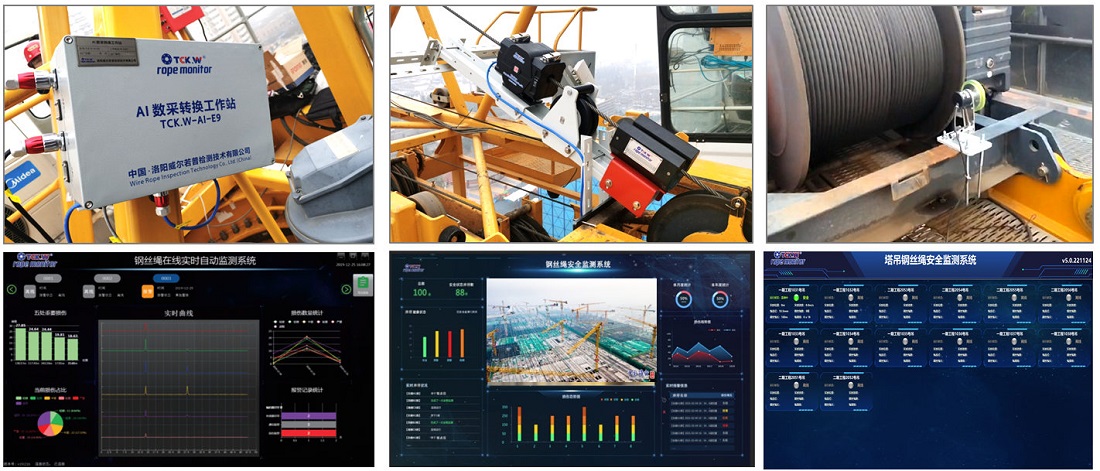

When exploring the microscopic physics phenomena of ferromagnetic materials,

the company's scientists discovered that the microscopic substances formed by

quantum many-body effects, such as "magnetic domains" and "electron spin

magnetic moments", have varying movement laws.

Applying a moving magnetic field to ferromagnetic materials can make them

have a moderate low-level magnetic energy product, thus forming a "memory

magnetic field".

Based on this discovery, the company's scientists invented a "magnetic memory

AI weak magnetic nondestructive testing technology", which for the first time

realized the intelligent monitoring of the entire life cycle of steel wire

rope.

The weak magnetic detection technology that can distinguish the physical

characteristics of materials under magnetic fields has subverted traditional

detection techniques and is at the international leading level in the field of

nondestructive testing of ferromagnetic materials.

Technical Parameters

(1) Inspection range of wire rope: Φ16-80mm;

(2) LMA inspection uncertainty: <±1%;

(3) Flaw positioning accuracy:≥99%;

(4) Inspection speed: 0-6m/s;

(5) Monitoring speed: 0-20m/s;

(6) Passing-through capability: Non-interferencewith warp, grease or deformation;

(7) Clearance between sensor and wire rope: 10-30mm;

(8) Max. amplitude of wire rope: <10mm;

(9) Sensor sensitivity: 1.5V/mT;

(10) Signal-to-noise ratio: S/N>85dB;

(11) Max. sampling rate: 2048times/m;

(12) Working voltage: AC220V±10%/50/60 Hz;

(13) Communication network: WIFI or industrial Ethernet;

(14) Docking communication protocol: TCP/IP, Modbus;

(15) Ingress protection: IP67;

(16) Working environment: -40℃-+60℃/RH 95%;

(17) Continuous working hours: ≥168h;

(18) Service life of equipment: ≥10 years;

Flaw Detectability

● Severe flaw: LMA reaches 8%-10% , real-time detectability 100%

● Serious flaw: LMA reaches 6%-8% , real-time detectability 100%

● Medium flaw: LMA reaches 4%-6% , real-time detectability 100%

● Minor flaw: LMA reaches 2%-4% , real-time detectability >99%

● Slight flaw: LMA reaches =2% , real-time detectability >95%

LMA reaches >1% , real-time detectability >95%

Inspection Repeatability

● Severe flaw: 100%,flaws inspection waveforms basically coincide

● Serious flaw: 100%,flaws inspection waveforms basically coincide

● Medium flaw: 100%,flaws inspection waveforms basically coincide

● Minor flaw: >99%,flaws inspection waveforms basically coincide

● Slight flaw: >95%,flaws inspection waveforms basically coincide

Inspection Accuracy

●Steel wire rope, coiled tubing metal cross-sectional area (LMA) loss rate detection error: < ±1%

● Broken wires quantitative error i n one lay length: <1 wire*

●Steel wire rope, coiled tubing dia. measure error: ±1%*

●Steel wire rope, coiled tubing measuring error of wire rope length:<0.2%

●Flaw positioning accuracy:≥99%;

To obtain detailed solutions, please submit a message or contact our online customer service for more information. >>>>>>>>>>>

What can

I do-——It can inspect all kinds of wire rope flaws such as internal, external broken wire,

abrasion,

corrosion, deformation, fatigue etc.