|

|

|

|

description:This article introduces the current status of steel wire rope detection technology, and expounds the advantages of weak magnetic steel wire rope detection technology and the working principle of the steel wire rope online automatic detection system. The fact that Datong Coal Mine Group has created significant safety and economic benefits using the TCK.W steel wire rope online automatic detection system proves that the steel wire rope detection technology based on weak magnetic technology is an inevitable choice for coal mines to create a new model for safety supervision of hoisting steel wire ropes.

CLC No.: TD532 Document Code: A Article ID: 1002-6029(2011)04-0044-02

1 Overview of lifting wire rope damage detection

Wire rope is an irreplaceable component in coal mine transportation and hoisting, which constantly maintains the safety of employees' lives and the safety of enterprise property, and has always been highly valued by coal mining enterprises. For a long time, coal mining enterprises have been using visual, manual, and caliper measuring methods to inspect the external damage of wire rope according to the provisions of the "Coal Mine Safety Operation Regulations", in order to judge the safety status of the hoisting wire rope; or regularly replace it according to the specified service life. Practice has proved that both manual detection and regular replacement are unreliable, and it is difficult to achieve the purpose of preventing wire rope breakage accidents. Therefore, coal mining enterprises urgently need to use wire rope nondestructive testing equipment to solve the three major problems of "hidden dangers, low efficiency, and waste" in the use and management of hoisting wire rope.

The special structure of the lifting steel rope determines that only by using nondestructive testing equipment to continuously detect internal and external hidden dangers of the steel rope online in real time and grasp its deterioration trend can we take decisive measures proactively to effectively eliminate possible rope breaking accidents. After years of exploration, Datong Coal Mine Group has selected the TCK steel rope online real-time automatic detection system based on weak magnetic technology to innovatively enhance the safety supervision mode of the steel rope, and has basically achieved the three management objectives of "safety, conservation, and efficiency".

2 Improve the selection of wire rope detection technology

There are non-magnetic and magnetic detection techniques for wire rope. Non-magnetic detection methods mainly include electric eddy current, mechanical vibration, ultrasound, optics, etc., which have not been widely applied in industrial fields; while magnetic detection technology, which can better adapt to the working conditions, is recognized as the most suitable detection technology for non-destructive testing of iron magnetic materials. There are two types of magnetic detection techniques: strong magnetic and weak magnetic. The former has a history of more than 100 years, and although some progress has been made, there are no significant breakthroughs in technology, and there are still defects such as poor passing ability, noise interference, and detection results affected by speed. It is almost impossible to achieve online detection of steel wire rope. The weak magnetic detection technology, which was developed in the early 2000s, uses high-sensitivity sensors independently developed in China to comprehensively innovate the detection principle and method, achieving major technical breakthroughs in the quantitative detection of internal and external injuries of steel wire rope, especially fatigue. The TCK.W weak magnetic detection technology uses a "Dou's element" sensor with high sensitivity and does not constrain the measured steel wire rope during detection, allowing non-contact "wide distance" detection. The detection equipment has good passing ability and the detection results are not affected by speed. It is considered by the industry as an advanced technology that has the greatest hope of achieving online real-time detection of steel wire rope.

After comparing strong and weak magnetic technology, Datong Coal Mine Group believes that to create a new model for improving the safety supervision of steel wire ropes, it is necessary to conduct online real-time detection of steel wire ropes. To achieve this, the world's leading weak magnetic detection technology should be selected.

3 Advantages of weak magnetic detection technology

The non-destructive testing technology for steel wire ropes is divided into non-magnetic and magnetic ones. The basic requirement for online real-time detection of non-magnetic steel wire ropes is to achieve continuous positioning, quantitative, and qualitative detection of the hoisting steel wire ropes in operation, and ensure that the detection results are not affected by factors such as detection speed, steel wire rope vibration or jitter. The TCK.W steel wire rope online real-time automatic detection system based on weak magnetic technology fully realizes these functions. The reason why this system can achieve online automatic real-time detection is that weak magnetic detection technology has unique advantages.

3.1High-sensitivity sensor technology

"Dou's element" sensor is the core technological key of weak magnetic detection. Based on the principle of spatial magnetic field vector synthesis, the "Dou's element" sensor provides a given magnetic field through the energy release element. This magnetic field is associated with the weak magnetic space volume differential along the axial direction of the steel wire rope, reflecting the comprehensive degradation characteristics of the steel wire rope, i.e. local defects (LF) and metal effective cross-sectional area loss (LMA). The sensor's magnetic balance element can convert these changes into corresponding electrical signal.

Due to the high sensitivity of the "Dou's element" sensor, reaching 5V/GS, the steel wire rope online detection system based on weak magnetic technology adopts non-contact "wide distance" detection, which makes it very easy for the steel wire rope to pass through and is not affected by any external factors. It can extract the steel wire rope damage signal online in real-time, accurately locate, quantitatively and qualitatively detect various internal and external damages such as broken wires, wear, corrosion, and fatigue, and evaluate the remaining load capacity and service life of the steel wire rope. The system has a detection speed of 0 to 13m/s and is not affected by factors such as steel wire rope vibration or jitter.

3.2 Theory of spatial magnetic field vector synthesis

The new theory of spatial magnetic field vector synthesis created by TCK.W is the theoretical basis of weak magnetic detection technology. This theory reveals and explains the variation law and quantitative relationship of magnetic energy potential of ferromagnetic materials under weak magnetic state. Based on this theory, TCK.W established a corresponding mathematical model. According to internationally recognized technical standards for steel wire ropes, after a large number of technical tests, the quantitative calculation of the loss of effective cross-sectional area of metal caused by various types of damage to steel wire ropes based on this mathematical model is accurate and fully meets the quantitative detection requirements of internal and external defects of steel wire ropes. This theoretical breakthrough has inherited the long-standing traditional magnetic detection technology principle, realized the qualitative leap of magnetic detection technology from qualitative detection to quantitative detection, and then completed the accurate, scientific and objective evaluation of the remaining load-bearing capacity and service life of steel wire ropes.

4 Principle of wire rope online detection system

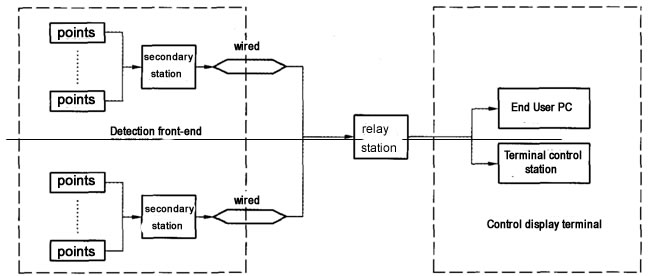

The TCK.W steel wire rope online real-time automatic detection system based on weak magnetic technology (see attached figure) adopts a reliable structural type to install the system detection device in an appropriate position that is easy to detect the hoisting steel wire rope. During detection, the weak magnetic loading device first carries out weak magnetic planning for the entire length of the steel wire rope. The detection device installed with "Dou's element" high-sensitivity sensors then performs "holistic" slicing detection on the steel wire rope, extracts the original detection signal and outputs it. The system's data acquisition conversion device (secondary station) receives the original detection signal and completes the prescribed mathematical model and information format conversion at the same time, achieving initial data processing and information storage. Through wired or wireless communication transmission methods, the running steel wire rope damage signal is transmitted to the multi-channel main control center (main control station) in real-time for comprehensive analysis and calculation, obtaining the detection results, and displaying the detection results in real-time at the display terminal. The system automatically prints the detection report and completes the archiving of the detection results. In addition, the system also has an acoustic-visual alarm system that can provide real-time alarm prompts for severe damage detected, and initiate emergency response measures according to the pre-set early warning plan to ensure safe operation of the equipment.

Figure Working principle of the Wire rope online automatic monitoring system

5 Application Practice of TCK.W Wire rope online automatic monitoring system

TCK.W steel wire rope online real-time automatic detection system for coal mine application: based on weak magnetic technology, the system uses a reliable structure type to install the detection device on the convenient position of the mine's shaft and shaftway for steel wire rope lifting, to achieve safe and scientific management of steel wire rope and safe use.

TCK's online real-time automatic detection system has a detection accuracy of 0.01% and can detect and evaluate various types of damage to steel wire rope, including wear, corrosion, fatigue, broken wire, and other hidden dangers. The system can also provide timely maintenance suggestions to ensure safe operation of the steel wire rope.

The system has achieved energy-saving, efficient and intelligent detection for more than 20 mines in Tongcoal Group. In just 4 years since its application, it has saved more than 20 million yuan in maintenance costs, reduced the failure rate of steel wire rope by 50%, and increased the service life of steel wire rope by 30%.

The system has also won the recognition of many coal mines. In the last 6 months alone, the sales of this system have doubled compared to the same period last year. It is expected that the sales volume of this system will continue to grow in the future.

。

6 Conclusion

The TCK.W Wire rope online automatic monitoring system can achieve comprehensive online automatic detection of steel wire ropes for major equipment and important facilities, creating a new safety supervision model for users, eliminating potential safety hazards, reducing labor intensity, and improving work efficiency. This has important practical and long-term significance for ensuring safe production in coal mines, improving economic efficiency, and promoting enterprise development.

[References]

[1] Dou Yutang, Guo Baozhong. TCK Steel Wire Rope Online Nondestructive Quantitative Testing System [J]. Coal Mine Machinery, 2001(8).

Author Introduction

Xue Peng (1982-), male, assistant engineer. Graduated from Taiyuan University of Technology in 2011 with a major in Mechanical and Automation Engineering. Currently employed at the Mechanical Section of the Mechanical and Electrical Management Department of the same coal group.

Duan Yuexin (1968-), male, master of engineering, senior engineer. Graduated from Nankai University Computer Science in 2002, has led research projects that have won the third prize in the Military Science and Technology Progress Award. Currently serves as the Vice General Manager of the R&D Center at Luoyang TIXIKANG Steel Wire Rope Detection Technology Co., Ltd.

上一篇: Research and application of automatic detection system for steel wire rope on line

下一篇: Application of electromechanical integration products in the production of Luoling Coal Mine

The application of TCK.W wire rope detection technology in academic journals

Editor's note: TCK.W has developed a weak magnetic rope detection technology that can real-time monitor the status of steel ropes 24 hours a day, 365 days a year, and locate, classify, and quantitatively identify various internal and external defects. Currently, more than 2,500 clients in 42 countries worldwide are using this technology. These clients have published papers on the safety and economic benefits brought about by this new technology in various academic journals. Here is a compilation of some of these papers for experts and scholars to explore and study in depth.。

论文名称

作者单位

publish:《Well construction technology》

publish:《Well construction technology》